-40%

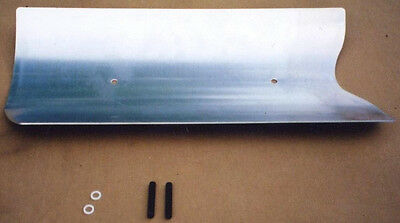

AVP01 Pontiac V8 326 350 389 400 421 428 455 Aftermarket Valley Pan Street Race

$ 29.04

- Description

- Size Guide

Description

New Aluminum Valley Pan - .089 thick! best one available!Eliminate the frustrating job of properly cleaning and the,often, poor sealing qualities of stock valley pans.

Pan clears all roller lifters - solid roller, hydraulic roller and of course, all flat tappet lifters.

This pan is intended for performance Pontiac V-8's and has no provision for a PCV valve.

Requires both valve covers to be vented.

Exclusive to Spotts Performance US made Aluminum Valley pan is the unique threaded stud with allen wrench adjustability. By installing the allen studs before the aluminum tray is installed - installation is simplified.

Included with pan are nylon washers and regular zinc hex nuts.

Instructions below:

The aluminum valley pan may be installed in various forms. Best results are just using RTV silicone with no gasket. The ultra black/gray Permatex works fine. Best results are from the “Right Stuff” also from Permatex. Right before pan is ready to install, run a small bead of silicone on the block and heads – do not use excessive amounts that could end up in your engine. Surfaces should be clean and dry. Lacquer thinner works well in surface preparation. Make sure the mating surfaces of the head and block have an extra amount of sealer to prevent leaks. Install supplied studs in block and place pan in proper position. When placing pan in position, it will not fit flush or all the way down. Tightening the pan will seat it. Install supplied nylon washers and nuts. Slowly stagger tighten nuts. When small amount of sealer is evenly squeezing out – STOP and let sealer dry. A small amount of sealer on nut, washer and stud will prevent nuts from loosening. Over tightening will cause leaks by causing pan to “curl” inward. On excessively milled heads, where block and heads do not have an even mating surface, the push rod cover gasket may be used. In this case, it is better to glue gasket to block/heads, let set or dry and proceed from instructions above. This will prevent gasket to “walk”. Since no PCV valve is used, both valve covers should be vented. Open breathers or a header scavenger system is highly recommended. This pan will clear all current available roller lifters and hydraulic roller lifters.