-40%

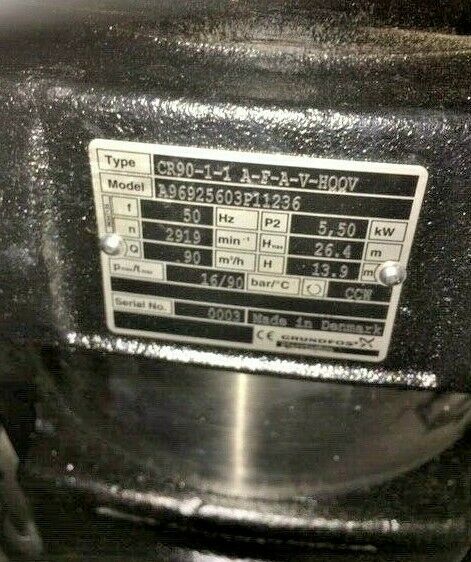

Grundfos CR 90-1-1 A F A V HQQV 5.5kW Vertical Multi-Stage Pump 415V (96124086)

$ 1108.8

- Description

- Size Guide

Description

Grundfos CR 90-1-1 A F A V HQQV 5.5kW Vertical Multi-Stage Pump 415V (96124086)Product acquired due to order cancellation, NON-Returnable.

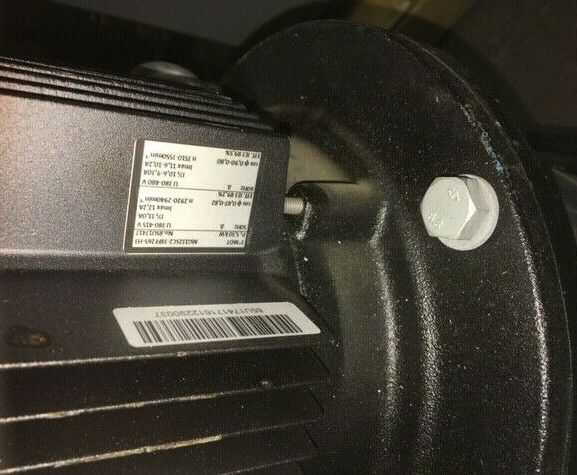

Product No.: 96124086 Vertical, multistage centrifugal pump with suction and discharge ports on same the level (in-line) enabling installation in a horizontal one-pipe system. The pump head and base are in cast iron – all other wetted parts are in stainless steel. A cartridge shaft seal ensures high reliability, safe handling and easy service and access. Power transmission is via a split coupling. Pipework connection is via DIN flanges. The pump is fitted with a 3-phase, fan-cooled asynchronous motor. Further product details The product carries the Grundfos Blueflux® label. It represents the best from Grundfos within energy-efficient motors and frequency converters. Grundfos Blueflux® solutions either meet or exceed legislative requirements such as the EuP IE3 grade. Steel, cast iron and aluminium components have an epoxy-based coating made in a cathodic electro-deposition (CED) process. CED is a high-quality dip-painting process where an electrical field around the products ensures deposition of paint particles as a thin, well-controlled layer on the surface. An integral part of the process is a pretreatment. The entire process consists of these elements: 1) Alkaline-based cleaning. 2) Zinc phosphating. 3) Cathodic electro-deposition. 4) Curing to a dry film thickness 18-22 my m. The colour code for the finished product is NCS 9000/RAL 9005. Pump A standard split coupling connects the pump and motor shaft. It is enclosed in the pump head/motor stool by means of two coupling guards.

The motor stool connects the pump head and motor. The pump head has a combined 1/2" priming plug and air vent screw. The pump is fitted with a balanced O-ring seal unit with rigid torque transmission system. This seal type is assembled in a cartridge unit which makes replacement safe and easy. Due to the balancing, this seal type is suitable for high-pressure applications. The cartridge construction also protects the pump shaft from possible wear from a dynamic O-ring between pump shaft and shaft seal. Primary seal: - Rotating seal ring material: Silicon carbide (SiC) - Stationary seat material: Silicon carbide (SiC) This material pairing is used where higher corrosion resistance is required. The high hardness of this material pairing offers good resistance against abrasive particles. Secondary seal material: FKM (fluorocarbon rubber) FKM has excellent resistance to oils and chemicals. Above 90 °C, FKM should only be used in media without water. The shaft seal is retained in the pump head by a cover and screws. It can be replaced without removing the motor. The chambers and impellers are made of stainless steel sheet. The chambers are provided with a PTFE neck ring offering improved sealing and high efficiency. The impellers have smooth surface, and the shape of the blades ensure a high efficiency. The base is made of cast iron. Both the suction and the discharge side of the base have two pressure gauge tappings. The pump is secured to the foundation by four bolts through the base plate. The flanges are fastened to the base by means of locking rings. Motor The motor is a totally enclosed, fan-cooled motor with principal dimensions to IEC and DIN standards. The motor is flange-mounted with free-hole flange (FF). Motor mounting designation in accordance with IEC 60034-7: IM B 5 (Code I) / IM 3001 (Code II). Electrical tolerances comply with IEC 60034.

WORLDWIDE/EXPRESS SHIPPING AVAIL...EMAIL FOR QUOTE.

WE WILL SHIP ON YOUR UPS ACCOUNT "RED" IF YOU WOULD LIKE.

RETURNS AVAIL...FREE INSURANCE OVER 100.00

INLAND ELECTRIC SURPLUS GROUP THANKS YOU FOR SHOPPING OUR STORE.

Shipping is Monday - Friday within 2 business days after payment has cleared. Returns are accepted within 30 days if item (s) is returned in the same condition and original packaging. Buyer to pay all return shipping costs.

Expedited shipping available.

PAYPAL ONLY PLEASE

THANKS FOR LOOKING HAVE A GREAT DAY!

PLEASE FEEL FREE TO ASK ANY QUESTIONS YOU MAY HAVE PRIOR TO PURCHASE.